Quality Assurance

- Home

- Quality Assurance

Inteco Electronics Quality Assurance

Our Principal is Quality is the Basis of All, Building Reliability, One Component at A Time.

As a professional IC components provider, Inteco Electronics take great pride in the quality of our products and the assurance we provide to our customers. We understand that quality is essential in ensuring that our customers’ end products are reliable, efficient, and perform optimally.

To ensure that every product meets our high-quality standards, we are not only making quality control by ourselves, but also working with professional Third-Party Test Labs.These labs are independent and specialized in testing electronic components, and they provide us with reliable data and formal test report to ensure the performance of our IC products.

There are the following IC Components testing programs you can choose as your needs:

External Visual Inspection

External visual inspection of IC components involves examining the package and lead frame for any visible defects such as cracks, scratches, or discoloration. The inspection may also include verifying the part number, date code, and other identifying markings on the component.

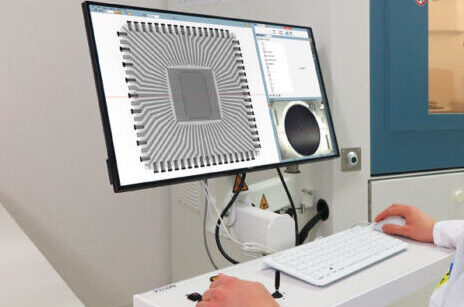

X-ray Analysis

X-ray analysis can be used to inspect the internal structure of IC components, including the die, wire bonds, and solder joints. This technique can identify any defects such as voids, cracks, or delamination, which can affect the performance and reliability of the component.

Heated Solvent Test

The heated solvent test can be used to determine the adhesion strength between the die and the lead frame or substrate. This test involves heating the component in a solvent to weaken the bond and then observing any separation between the die and the substrate. This test can identify any issues with adhesion or bonding that may affect the reliability of the component.

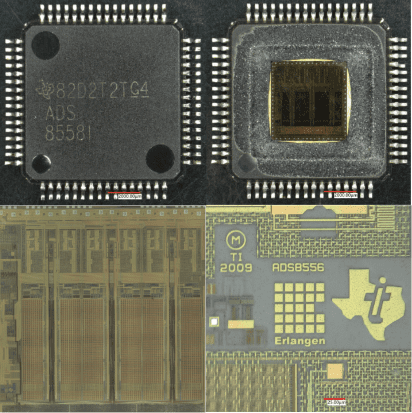

Decapsulation and Die Analysis

Decapsulation and die analysis involve removing the packaging material from the IC to examine the die and wire bonds. This process can reveal any issues with the wire bonds, such as cracking or corrosion, or defects in the die, such as voids or cracks. This analysis can help identify the root cause of any performance issues or failures in the component.

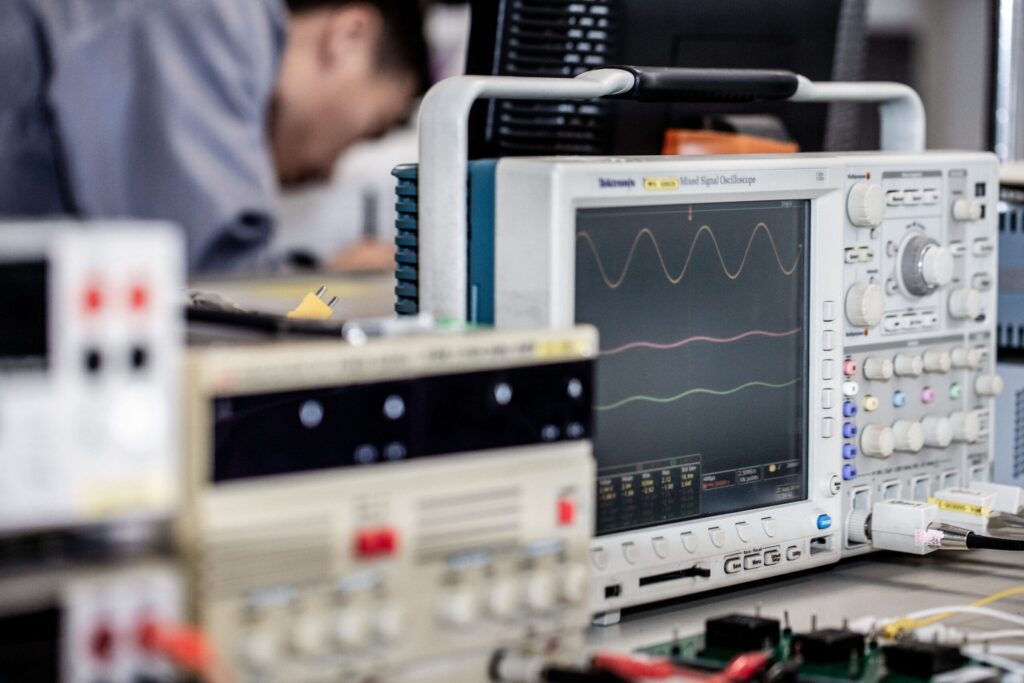

Electrical Test

Electrical testing of IC components involves verifying that the component meets the required electrical specifications. This can include testing for parameters such as power consumption, voltage levels, current levels, and signal integrity. Electrical testing can help identify any issues with the functionality or performance of the component.

Function Test

Function Test is an essential process for ensuring that IC components are working correctly and meet the required specifications. It involves applying a set of signals or stimuli to the IC component, and then measuring its response. Function testing is a critical process in ensuring that IC components perform as expected and meet the required specifications.

At Inteco Electronics, we believe that quality is non-negotiable, and we are committed to providing our customers with the highest quality IC components. By working with third-party test labs and implementing rigorous quality control measures, we can assure our customers that they are receiving reliable and high-quality products.

Get Started Today!

Ready to take your business to the next level?

Contact us now to experience the quality and reliability of our IC Components and services. Let us be your trusted partner in success!

Ask For Quote Now

Note: Your email information will be kept strictly confidential.